Our plans are being finalized and negotiated between the shareholders, the owners, our management staff and our partners in the Netherlands.

We have two initiatives:

1. Operational plans for 2016 and

2. Long-term plans, 2017-2021

Operational and sales plans for 2016 are being detailed at this moment and include the following objectives:

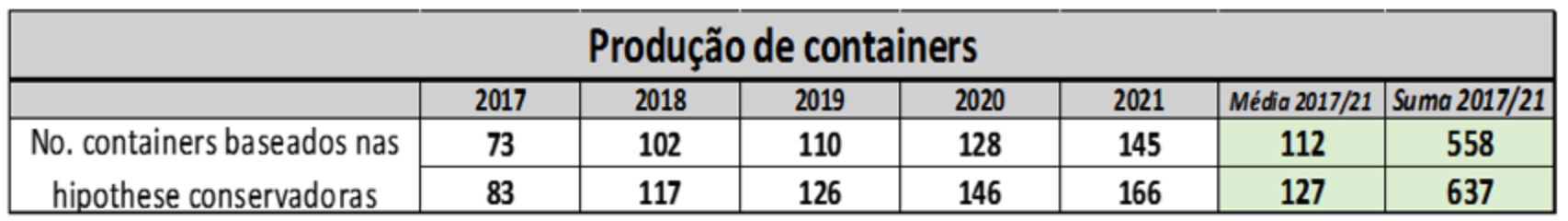

At the same time, we programmed an investment plan for this next year: However, that is not all! We are getting ready for the following five years, when the planting will be in full production:

The future is promising!

The future is promising!

This is how we intend to achieve these future goals.

We will be keeping focused on six lines of action:

- Giving priority to Limes, while strengthening the Coffee

- Obtaining an overall average productivity in the Lime Orchard of not less than 45 tons per hectare (and also > 50 sacks of green coffee)

- Focusing on quality and fertility of the lime orchard to maintain our present utilization rate for export of no less than 82% in 2017 to 86% in 2018

- Keeping fixed costs to no more than 26%

- Adopting management practices based on the proposals by GlobalGAP and consolidating and refining the techniques of precision agriculture

- Investing in our personnel

Priority on limes and focused attention on Coffee

We had to accept that the production, processing, exporting and distribution in Europe of LIMES is the main priority of Peralba. If initially the project began as an experiment to ‘ fill ‘ non-productive areas and so protect the Atlantic Forest, 10 years later, the limes crop has become the flagship of the farm and a business with great potential and attractive returns. We still have to face many challenges ahead, but we are now able to foresee them, evaluate them quickly and respond intelligently. The trees are healthy and well fed, we understand the characteristics of our microclimate, we know what our particular soil needs to be able to sustain full production and we are supported by very experienced agronomists: all we need now is to proceed with care and attention.

This attitude will be used also for the coffee plantation. Although this crop contributes less to the overall financial results, we are investing carefully to make it profitable. For example, this year (2016) we did a drastic pruning to reinvigorate the orchard. This will reduce the harvest next year, but will allow us to return to the productivity heights of 2011. And we want to improve on them: our goal is 60 bags per hectare in 2017 and possibly even 80 by 2018. And if the drought comes back, this time we will be ready with emergency irrigation.

The other crops (piassava, rubber, dendé, eucalyptus) will also receive attention and will be maintained, but with the condition that they will not distract us from our priorities.

Productivity

We achieved an average of 19 tons of limes per hectare in 2015 and we intend to reach the goal of 26 tons in 2016. However, we would like to be surprised with the results in 2017: with the entry into full production of the Peralba Sucupira area, we should reach well above the 35 tons/ per hectare … and if 35t/Ha is good number, 40/50 is better… and reachable!

At the same time, we are conducting an aggressive replanting program: 15000 new seedlings will be planted in 2016 and between 5,000/8,000 in each of the following years. This means that we will be keeping the plantation in a state of continuous renewal at an average level of 66,000 trees in full production.

In the coffee plantation, we want to reach at least the same levels of 2011. Then we harvested 48 bags of green grain per hectare. In 2015, we made a drastic pruning and in 2016 probably we will not have great results, but from 2017 onwards we expect no less than 60 bags per hectare.

The other crops probably will continue to present levels as their impact on operations and financial results are minimal.

Utilization rate

A key factor for the profitability of the venture is the utilization rate, the ratio between the total quantity of fruit produced and the amount of fruit packaged for export and evaluated as good when you arrive in the Netherlands.

In other words, to achieve such rate we must look at a combination of many years of planning and fieldwork, the adoption of field practices, timely and surgical interventions on pests, development of handling processes from harvesting to transporting, packing and shipping: every step of the process has been carefully planned and delicately executed and honed through the years! We learned the art well!

In the last three years, our rate rose dramatically as we adopted new management practices and better plantation handling, learnt from our experience. Today, we are working at not less than 80% utilization for export, extraordinary! This is still not acceptable- at least, not acceptable by us (and us means ALL of our employees, not just the owners or the managers. 86% is our collective goal for the next few years! And let it be said: this is extraordinary indeed!

Costs

Costs are and will be kept low as we shall reap benefits to scale. This is one of the key elements of our business strategy in the coming years: keep fixed costs down to no less than 26% on sales or no more than 10% increase from 2017 projected levels. In addition to this being a prudent and wise practice, we shall be financially solid in case of exceptional events.

Management practices and precision agronomics

Com quatro anos de certificação GlobalGAP, podemos dizer que nós introduzimos e adaptamos com sucesso as práticas recomendadas… aliás, em inúmeras esferas, as superamos!

Chegou a momento de sofisticar os processos com técnicas de agricultura de precisão. Já introduzimos vários procedimentos usando essas tecnologias, mas sempre os deixamos em segundo plano focando na solução de eventos mais urgentes ou imediatos. Vamos revisitar essas técnicas e aprimorá-las:

Use of drones. For identifying pests, spraying interventions and watering levels. We did use drones to map parts of the plantation and produce a mosaic of several blocks with multispectral camera. The results were surprising, but we let it drop, as we did not have the in-house expertise to sustain it adequately. There is a clear need for this new discipline and we are considering changes in the management structure to fit such evolution (2017-2019)

Weather stations. We have two full seasons (DAVIS) ready for installation in the fields, but they need to be upgraded to send data to the farm office and from there to the internet. Then we will have to train management to use the information correctly. It will take between two to three years for the value of such a system to be understood, accepted and for relevant actions to be correctly executed (2017/2019)

Cameras in the packing house. (and a day also in the fields… why not?). The idea is to put cameras in the packing house to control the selection process and packaging of fruit from a distance. We dream that one day that our customers will be able to view in real time how their container is being prepared! It may seem little, but two of our clients in the Netherlands received the idea very well! (2018/2019)

Electronic OTC process and operational control in the field. With the use of tablets, connected to the cellular network, it will be possible to monitor the operations in the field in real time or, at least, get all the information of spraying or harvesting at the end of the day, without the daily exercise of capturing this information on paper and later transfer them to the computer (2017-2020)

Equip tractors with GPS and tracking system. Despite being careful, sometimes drivers do not spray a line, drive faster than recommended, spray in hours that they should not, report non-completed activities as completed, etc. etc. A tablet or even an iPhone would mark the paths of each tractor, time, speed and other information that would allow to monitoring of the work done with far greater precision than today (2017)

Emergency ferti- irrigation. We have a lot of water by the perennial streams that cross the lime crops, and are using these to fill our tank when spraying. It is not much water, usually 2000 liters, but we have improved the efficiency and effectiveness of the process. A project, which must be approved by EMBRAPA and the relevant governmental bodies, will allow the use of such water in periods of extreme drought and will drastically reduce the need for foliar spraying: sub-surface irrigation, a well-structured program of emergency irrigation and carefully dimensioned plant feeding (2018-2021).

Such sub-surface irrigation is a totally new technique not yet used in Brazil with limes. This method uses minimal amounts of water, easily obtainable from our streams and will not demand complex permits by State authorities. We consider introducing this method as soon as possible (2017-2018)

Bet on our people

Since 2010 we decided to develop people who are dedicated to the company, instead of looking for ‘readymade’workers. Today, we have a team of dedicated workers who have accompanied us for at least 4 years, some for nearly 8. These will be our leaders and we shall invest in them for the future. We shall have an innovative sharing program, capable to adequately reward them for their dedication to the company. And when they leave, if they leave, they will be far more prepared and better workers than today. Reading and writing are still impediments to some workers and hamper their ability to express their leadership and managerial abilities. With the opening of the Peralba School for the young (3/14), we shall have also specific evening programmes for the adults, not only for our staff, but also for everybody who will want to participate. With these elements at the ready, we shall guarantee that the 2017-2021 programme will be a success.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)