The Limes

The choice to invest in limes was not casual: statistics were carefully analyzed, the value chain links identified, containers purchased from third parties and exported to verify the import and distribution difficulties in the Netherlands and in Italy, just to mention few once the analysis was done.

We certainly did our homework before we committed any investment in this business: the historical series heralded a steady growth in the last 15 years (3% annual steady growth) while the future projections of consumption have never been assessed by several official and government bodies, at less than 6% for the 5 years into the future.

Our limes business went through two major cycles before we were sure that it was a viable and attractive business:

The initial phase of exploration of economic viability. We purchased fruit in Cruz das Almas, packed in local packing houses, exported to Europe, and then evaluated the costs and profitability of each link in the value chain. The productive potential of the future plantation is clear: its wide area climate, the microclimate in the South of the Recôncavo da Bahia, the quality of the soil, the absences of traditional pests, the negligible ecological impacts on the Atlantic forest and the possible effects of the proximity of the forest to the plantation.

This testing period lasted from 2006 to 2007.

In 2008 we planted the first 12 hectares in the Peralba Italia. Then 30 and finally 20 by 2010.

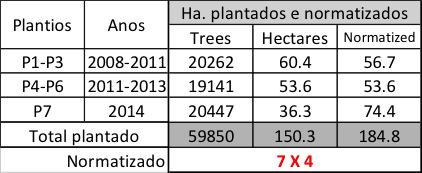

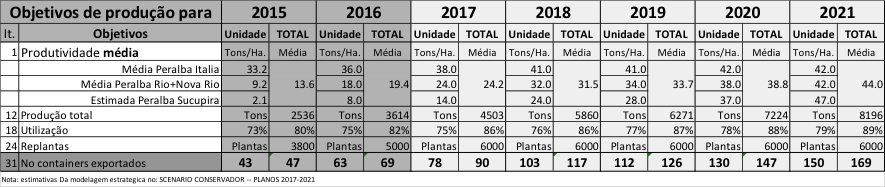

We call this new cycle the Aureus or Golden Period. The plantation and the limes business (or as some said our maturation in the understanding of the agro-business):meaning, we do not need to expand more above the approximately 160.3 hectares planted. This dimension would be an ‘optimum’ level of production and productivity without any marginal increase in costs: then we would normalize the whole plantation at a standard space of 7m X 4m per tree, we will reach an equivalent size of 196.1 hectares planted. This is plenty to make us independent from external suppliers and then not to incur in another steep increase in personnel and equipment. In other words: for the next five years (from 2017 to 2021) production levels will increase 584% from 2014 levels of 1200 tons/annum, while fixed costs will increase 28%!! It was a sort of pleasant discovery: till 2013 we had adopted all sorts of densities throughout the plantation, from 6m X 4m to 6m X 7m, 8m X 4m, even 8m X 7m, usually under the recommendation of a multitude of visiting ‘experts’.

In 2014 we planted 46.7 hectares at a 7m X 2m (and even 7m X 1m in certain patches. Our soil analysis confirmed that there was high fertility in older patches.). And since 2013, we replanted or substituted all nonproductive trees at 7m X 2m, and even 7m X 1.5m in some cases. When we compared such solutions with the productivity per hectare of the Brazilian standard of 7m X 4m, we realized that our standard density of 7m X 2m (that by 2017 will be in 95% of the plantation) and would bring us substantial gains: if the ideal productivity per hectare of the standard density of 7m X 4m is 30/35 metric tons per hectares, we could expect productivity levels of 52.3 tons per hectare or more, if we worked exceedingly well.

What does that mean? That we can export a minimum of 100 containers, starting in 2018, and up to 170 containers or maybe more by 2021. A lime tree lives on average between 16 and 32 years. We reached a plateau in costs that will increase by 3% to 5% per annum, irrespective of the volumes produced and after eight years, since 2008 our team is fully trained. We are achieving excellent efficiency and efficacy parameters (per hectare, per lot, per employee, per crate, per ton, per hour tractor, per man day or FTE, per Kg of fertilizer per Ha, per packed carton, per no of cartons packed per day per packer, per % utilization for export and we intend to maintain these KPIs, but we also intend to improve them, slowly and continuously

We feel we are doing well and will continue to do so, and will just keep on producing at least with the current quality.

We intend to work “always a little better” and “always a little further” than today.

A phase of consolidation. Between 2012 and 2016, we built and started operating our own packing house and became fully committed to the export business.

Initially all went according to plan. With the 2012 drought and the almost total disappearance of our supplies from Cruz and Mangabeira, we had to face a major decision: either to redirect our strategy to a major expansion effort and reach a level of production that would make us independent of external suppliers, or abandon the business. It became evident that our successful strategy would be to reach volumes that would allow us to commit to and fulfill delivery programs to our partners in the Netherlands: the damage from the drought had been minor (principally due to the innate resilience of the lime trees and to the characteristics of our microclimate). Rains returned that year (and even in that year we received almost 1500mm of rain!), and we acted immediately according to our new strategic posture.In that same year, 2012, we planted over almost 28000 trees in the Peralba Rio and Nova Rio. In 2014 we planted over 35000 new trees in Peralba Sucupira at densities of between 7m X 2m and 7m X 1.3m!.With a small investments in emergency irrigation, we prepared ourselves to survive any bad weather coming our way! We felt lucky and strong… and the following years confirmed such conclusions.Maybe we can add a mini second cycle to this period: the preparation of the farm for its full potential in what we saw as the emerging Areus (Golden) period of the Peralba Limes plantation. This mini cycle started in 2015 and will be completed by the end of 2016, then we will enter in 2017 with the whole farm in full production and with new investments in processes, management and ferti-irrigation! With this we would enter the following cycle.

It means that over the next few years we need:

- To sharpen our management (embracing the techniques of precision agriculture more’)

- To make better use of the computer tools (e.g. bringing real time processes into the field, particularly with the use of tractors)

- To improve our facilities (with bore holes to feed the emergency irrigation system already in place and introduce ferti-irrigation schemes, maybe even with subsurface dripping)

- To develop our key workers technically, teaching our tractor driver to use electronic instruments, send our field and harvest mangers to formal courses, technical development programmes at EMBRAPA, bring or institute field days led by specialized agronomists, etc.

- To open new markets in Europe, Canada and the Middle East

We can do all this, slowly, with caution and firmness: the team is good and is ready for these challenges.

We will act at the same time to improve the following area, in:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)